Closes: July 5th, 2023

Continue readingLab Technician

Closes: July 5th, 2023

Continue readingAnnouncing New Thermax® Partnership in Mexico

Cancarb Limited is pleased to announce the appointment of R.D. Abbott de México S. de R.L. de C.V (RDAbbott), as Cancarb’s new authorized distributor for Thermax® brand thermal carbon black in Mexico.

Continue readingRefractories

Thermax® application Refractories Thermax® carbon black can improve performance of monolithic, castable, carbon brick and basic carbon brick refractories. It can enhance resistance to thermal shock, heat, chemicals and active slag, increase refractory density, and improve in-situ carbide formation. Castables containing Thermax® require less water to reach normal casting flow, resulting in higher density and […]

Continue readingMillathane

Thermax® N990 was tested in a millable polyurethane compound. Utilizing N990 in place of highly reinforcing fillers resulted in lower viscosity, lower compression set, and higher resilience.

Continue readingFKM Automotive Gaskets and Seals

Thermax® N990 replaced N774 in an FKM seal compound resulting in reduced viscosity, lower cost, and equal or better sealing.

Continue readingEPDM Engine Mount

Thermax® N990 replaces N550 in an EPDM engine mount compound resulting in reduced viscosity and increased metal adhesion.

Continue readingCarbon Composites

Thermax® application Carbon Composite When added to the resin before impregnation, Thermax® carbon black can increase carbon deposition thereby reducing the time and cost involved in densification of carbon-carbon composites. It is also a premier product for thermal insulation in CVI (chemical vapour infiltration) and graphitizing furnaces. Thermax® Grade N991 Thermax® Click for details Thermax® […]

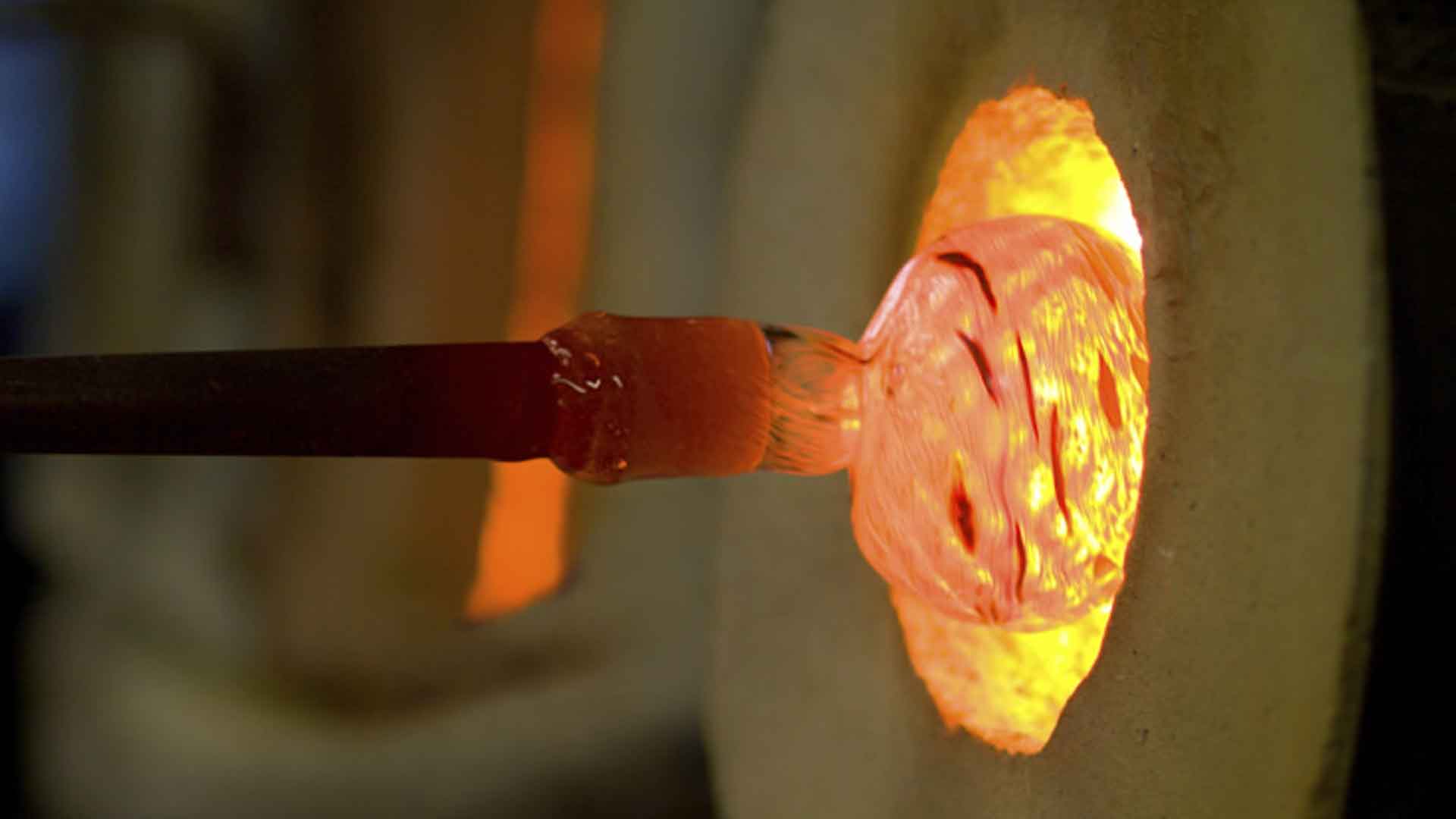

Continue readingCeramics

Thermax® application Ceramic Previous image Next image The particle size distribution and chemical purity of Thermax® make it an excellent product for porosity control in ceramics manufacturing. It can also serve as a high purity reducing agent in making products such as titanium diboride. Thermax® is also an ideal choice for insulation of high temperature […]

Continue readingSpecialties

Thermax® application Specialties Previous image Next image The high chemical purity of Thermax® carbon black makes it an ideal candidate for specialty and advanced materials where inorganic contaminants are undesirable. Thermax® Grade N907 Thermax® Stainless Click for details Thermax® N907 Stainless has a low extractable organics content. Specification Sheet N908 Thermax® Stainless Click for details […]

Continue reading