Thermax® application

High temperature processes require high performance insulation materials to minimize energy loss and maintain ambient plant temperatures acceptable for personnel and equipment. Thermax® carbon black effectively addresses conductive, convective and radiative heat loss from furnaces and reactors at temperatures up to 3,000 ºC.

Today, more and more advanced materials are treated and produced in high-temperature furnaces and reactors, where operating temperatures can exceed 3000°C; therefore the demands on high-temperature insulating materials have increased. Medium thermal carbon blacks – with their low thermal conductivity and inertness – make excellent insulating materials in high-temperature, non-oxidizing environments.

THERMAX® Powders from Cancarb are medium thermal carbon blacks produced from the thermal decomposition of natural gas. Manufactured with state-of-the-art processing and materials, THERMAX® Powders offer unsurpassed quality and consistency. Even better, they are available at only a fraction of the cost of synthetic graphite and carbon felts.

Thermax® Advantage

- Low combustibility and chemical reactivity due to inert surface chemistry and high carbon purity.

- Superior resistance to temperatures up to 3200°C.

- Low ash content to prevent clinker formation and reduce product combustion.

- Excellent insulation against radiant heat.

- Excellent packing with no tendency to flow or run after installation.

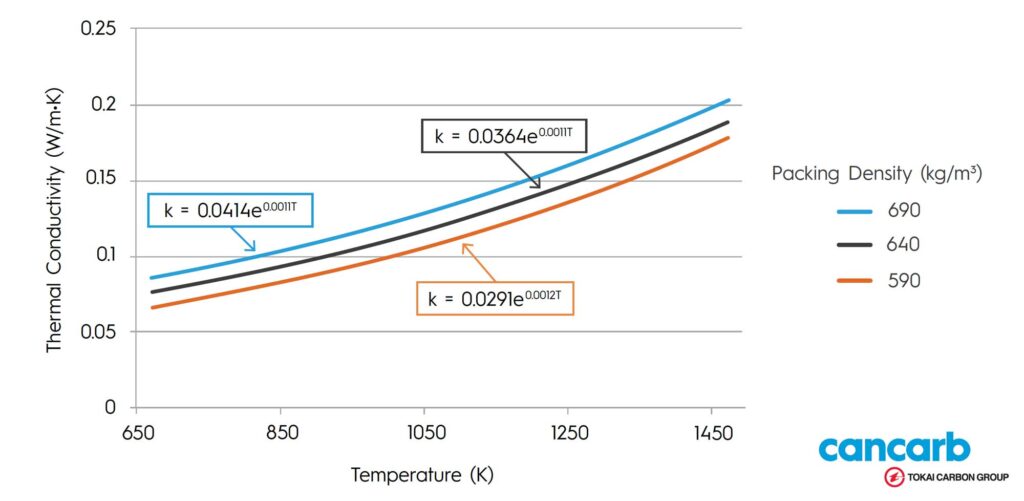

Thermal Conductivity vs Temperature

Thermal Conductivity of Thermax N991 at Different Packing Densities

Low Thermal Conductivity

A prerequisite of any candidate material for furnace and reactor insulation is low thermal conductivity. The thermal conductivity of THERMAX® is measured in accordance with standards set by the ASTM and is similar to graphite and carbon felts. (This measurement was made using the test “Steady State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded Hot Plate Apparatus” – ASTM C-177). Laser flash analysis (LFA) has also been used to measure thermal diffusivity.

End Use Recommendations

When employing THERMAX® Powders as an insulation medium, we recommend that the powder be packed as tightly as possible. These powders can’t be “over packed”. Tight packing ensures uniform conductivity and eliminates void spaces which can create hot spots and increase product combustion.

The Unique Properties of Thermax®

Non-carbon impurities can produce clinker formation and hot spots which jeopardize reactor /furnace integrity. THERMAX Powder is produced from a sulphur-free methane gas feedstock – and Cancarb’s unique processing steps ensure a final product almost completely free of impurities. Low ash and extremely low sieve residue levels exemplify the high purity of THERMAX Powders.

Thermal black exhibits the highest degree of layer plane order among carbon blacks, reducing both the number of exposed layer plane edges and the occurrence of chemically reactive sites. That means THERMAX Powders are much more chemically inert and less combustible, giving you insulation that can withstand elevated temperatures and hostile environments.

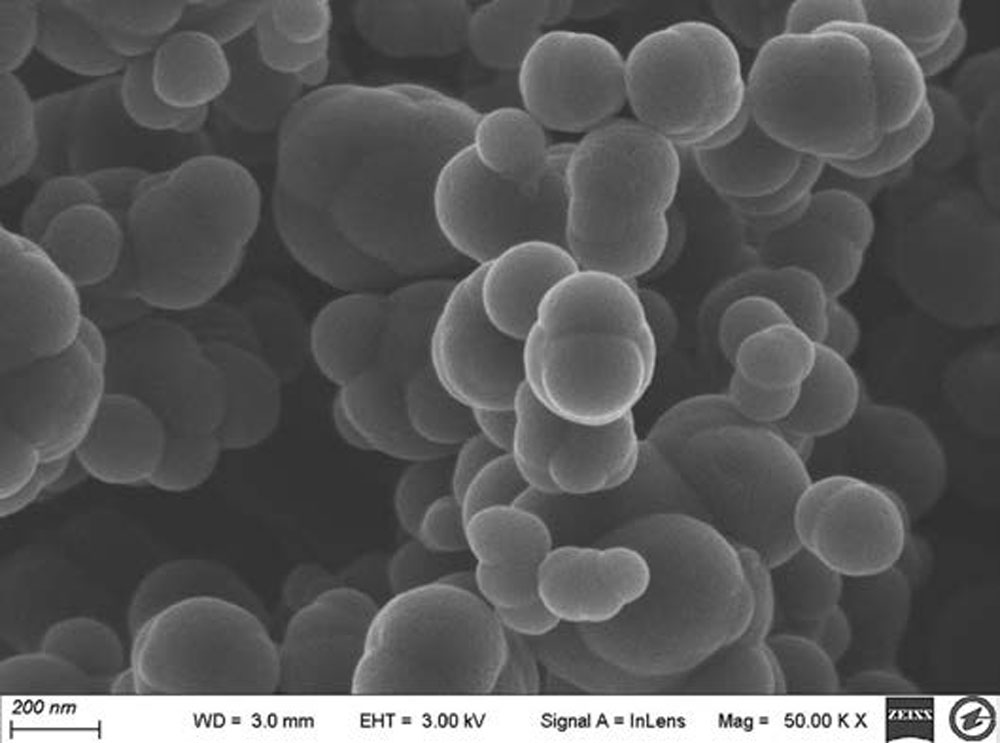

A large particle size provides a low surface area per unit mass. Medium thermal black has the largest particle size of any carbon black. THERMAX Powders have a typical average particle diameter of 225 nm, with a range between 100 and 600 nm. The low surface area of THERMAX Powders reduces chemical reactivity and increases the life of the insulation.

Carbon black particles tend to fuse into clusters or reticulate structures. Thermal black is relatively free of any structure and consists mostly of 1-3 particle aggregates. That means particles of THERMAX Powder pack very well and reduce void spaces, which in turn reduces insulation degassing time and ensures a uniform and consistent insulating layer.

A Variety of Grades to Choose From

Not all furnaces and reactors are alike, so not all customer insulation requirements are the same. That’s why Cancarb offers four grades of THERMAX® Powder to meet individual requirements. All grades provide the same low thermal conductivity.

Our regular Thermax® Powder N991 offers the unique advantages of medium thermal carbon black at an economical price.

Stainless Powder is a low aromatic content (toluene extractable) grade. The low level of extractables reduces off-gassing at elevated temperatures.

This high carbon purity grade has reduced ash levels. These extremely low levels reduce carbon loss and extend the life of the insulation.

This is the highest carbon purity grade of THERMAX®, combining the advantages of Stainless and UltraPure in one product. It is one of the world’s purest forms of industrial carbon.

Parameter | ASTM Designation | N991 | N908 | N991UP | N908UP |

|---|---|---|---|---|---|

*Tests are performed generally in accordance with ASTM | |||||

Sieve Residue | D1514 | ||||

60 Mesh Max % | .0030 (30) | .0030 (30) | .0005 (5) | .0005 (5) | |

325 Mesh Max % | .0250 (250) | .0250 (250) | .0050 (50) | .0050 (50) | |

Magnetics on 325 Mesh (max) | .0005 (5) | .0005 (5) | .0005 (5) | .0005 (5) | |

Nitrogen Surface Area, m2/g | D6556 | 7.0-12.0 | 7.0-12.0 | 7.0-12.0 | 7.0-12.0 |

Oil Absorption Number (OAN) cm3/100g max | D2414 | 44.0 | 44.0 | 44.0 | 44.0 |

Ash Content % max | D1506 | 0.2 | 0.2 | 0.02 | 0.02 |

pH | D1512 | 9.0-11.0 | 9.0-11.0 | 4.0-8.0 | 4.0-8.0 |

Toluene Extract % max | 0.5 | 0.15 | 0.5 | 0.15 | |

Heat Loss % max | D1509 | .1 | .1 | .1 | .1 |

Total Sulphur % (ppm) max | D5453 | – | – | .006 (60) | .006 (60) |

Learn more about Thermax® as High Temperature Insulation

Thermax® Grade

N990

Thermax®

Click for details

Thermax® N990 consists of uniform soft pellets which are easy to disperse in most applications, yet can withstand the rigours of transportation.

Specification SheetN991

Thermax®

Click for details

Thermax® N991 powder is a non-pelletized product designed for use in low shear force mixing systems.

Specification SheetN991UP

Thermax® Ultra Pure

Click for details

Thermax® Powder Ultra Pure is a non-pelletized powder form of N990UP.

Specification SheetN990

Thermax®

Thermax® N990 consists of uniform soft pellets which are easy to disperse in most applications, yet can withstand the rigours of transportation.

Specification SheetN991

Thermax®

Thermax® N991 powder is a non-pelletized product designed for use in low shear force mixing systems.

Specification SheetN991UP

Thermax® Ultra Pure

Thermax® Powder Ultra Pure is a non-pelletized powder form of N990UP.

Specification SheetTECHnical bulletins

Thermogravimetric analysis (TGA) is carried out on N991 and N991UP samples under isothermal conditions.

Thermal Conductivity of N991

The thermal conductivity of N991 versus temperature at different packing densities is measured. Also, the high temperature thermal conductivity is measured using LFA.